Transmission technology specialist Xtrac will unveil more advanced transmissions at Europe’s premier motorsport show taking place on 9-12 January 2020 at Birmingham’s NEC. Uniquely, the technology includes an e-axle for the first electric-powered cars to compete in the 2021 to 2024 FIA World Rallycross Championship. The company is also taking the opportunity to recruit apprentices and machinists as well as student, graduate and professional engineers interested in pursuing a career within the motorsport and high-performance automotive industry sector.

“Our ability to deliver a competition-ready EV gearbox reflects our continuing investment in transmission technology,” says chief executive Adrian Moore. “No other supplier can deliver a motorsport EV gearbox virtually off the shelf, which is why the motorsport industry acknowledges Xtrac as the world’s leading supplier of motorsport transmissions. I’m delighted, of course, that these vital commercial contracts also enable us to create new jobs within our industry.”

Moore foresees an exciting future for Xtrac both within the UK motorsport industry and on the global stage: “We have compelling technology to help make motorsport even more exciting, which also influences the crucial evolution of the next generation of road cars.”

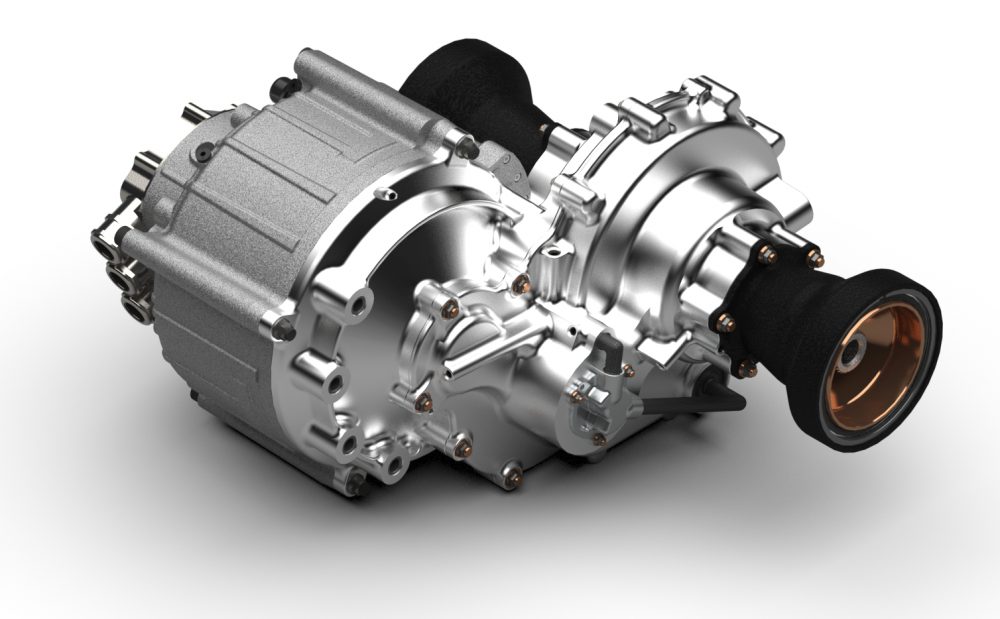

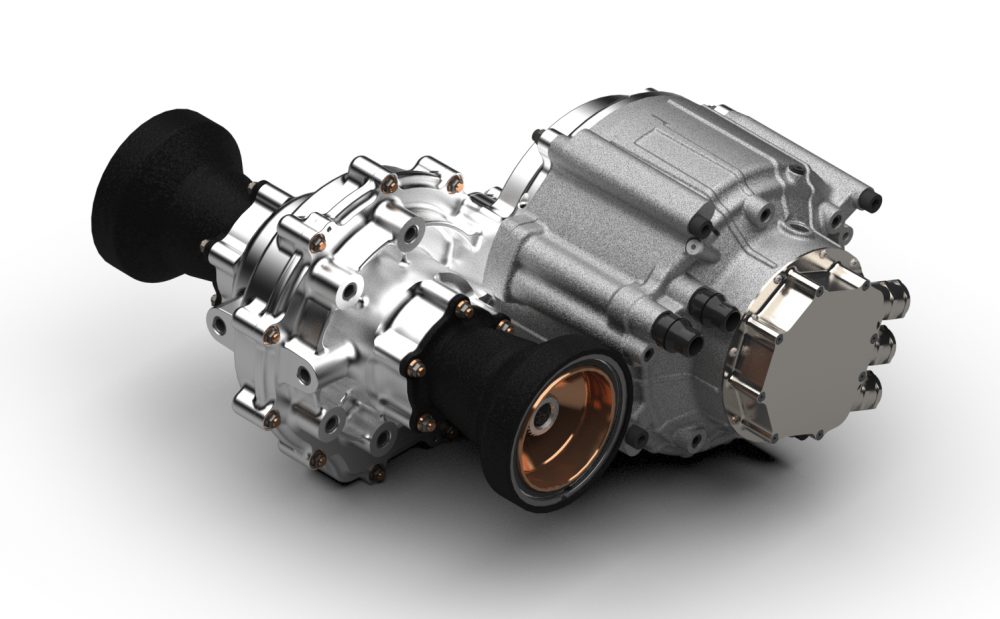

Xtrac’s P1316 e-axle, developed for cars competing in the FIA World Rallycross Championship from 2021 onwards, underscores the company’s distinctive range of integrated lightweight electric vehicle (ILEV) transmissions. Xtrac will supply the e-axle to Austrian company Kreisel, which the FIA has selected as the supplier for the phased introduction of a battery-powered propulsion system into this major race series with Kreisel responsible for the state-of-the-art motors, inverters and battery. Each 4WD vehicle includes two single-motor e-axles – one for the front axle and one for the rear.

Xtrac’s latest addition to its ILEV range complements technical advancements in its highly efficient and lightweight Formula E transmission systems. The P1316 e-axle has an overall ratio of 7.90:1 and is suitable for use with motors with a power rating of 250kW and an input speed up to 15,000 rpm. Lubrication is by an internal eccentric rotor pump with pressure feed to all critical areas, a semi-dry-sump oil pickup to minimise churning losses and optimise overall gearbox efficiency, with the option to fit an externally mounted oil cooler.

The differential is a multi-plate ramp type limited-slip differential with adjustable pre-load which, as an option, can be adjusted externally. Output flanges are explicitly designed for the application, meaning that the driveshaft length can be optimised for each vehicle type if required. Weight of the P1316 e-axle is a class-leading 21kg (dependent on specification) thanks to the use of Xtrac’s own ultra-high specification XM023 material for the highly loaded and weight-optimised components. Although its initial application is for battery-powered Rallycross vehicles, Xtrac has designed the gearbox to be suitable for circuit racing as well as electric touring cars.

Xtrac is a significant exporter and key supplier within Europe’s highly integrated motorsport industry supply chain. To celebrate having supplied more than a thousand integrated valve actuator (IVA) gearchange systems for motorsport gearboxes, which is a record achievement in the context of the motorsport industry’s ultra-low volume production of vehicles, Xtrac will display a commemorative gold anodised unit. Suitable for use on most Xtrac motorsport gearboxes, its P1254 gearchange unit, jointly developed with Mega-Line in Germany, has proven popular with customers, due to its reliability, compactness and unrivalled performance.

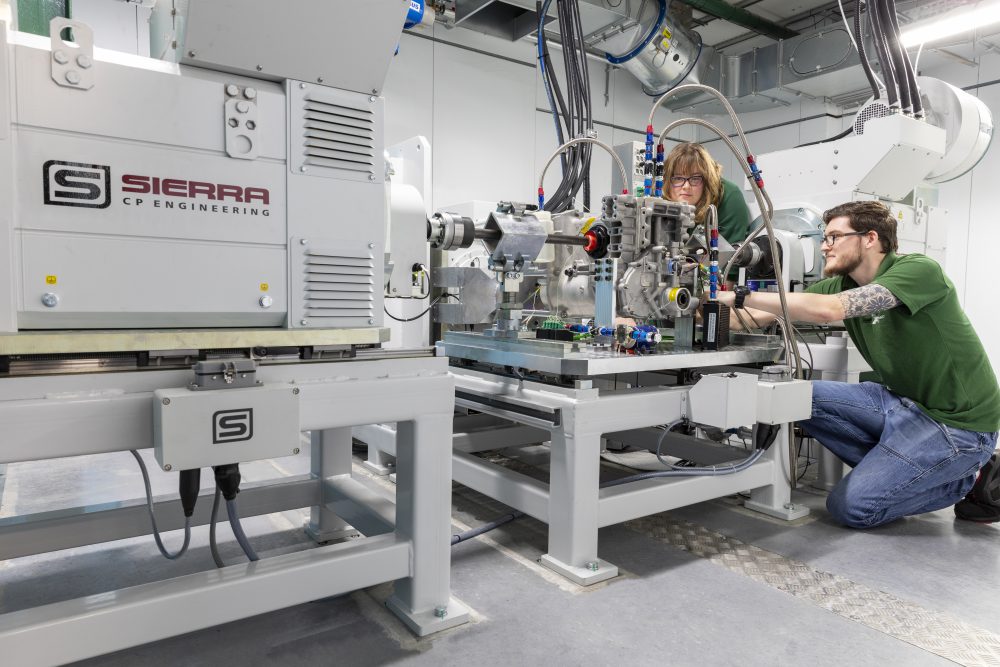

Continuing the company’s substantial capital investment programme, Xtrac has recently commissioned two new test rigs to enhance its end-of-line testing and accelerated duty cycle development capabilities. It has designed each 200kW test rig to a rigorous specification. Supplied by Sierra-CP, they consist of 3-axis and 4-axis rigs. The latter allows twin input drives, essential for testing the latest twin motor ILEV transmissions. Use of a battery emulator in the future will enable testing of complete integrated electric drive unit transmissions with the vehicle’s motors in-situ.

Recent investment also includes Xtrac’s sixth Kapp gear-grinding machine, delivering world-class gear manufacturing capability. The Kapp KX500 Flex adds not only the latest gear grinding precision and quality but also shortens manufacturing lead times. Moore says the machine is state of the art and offers “better capability than any of our direct competitors.”