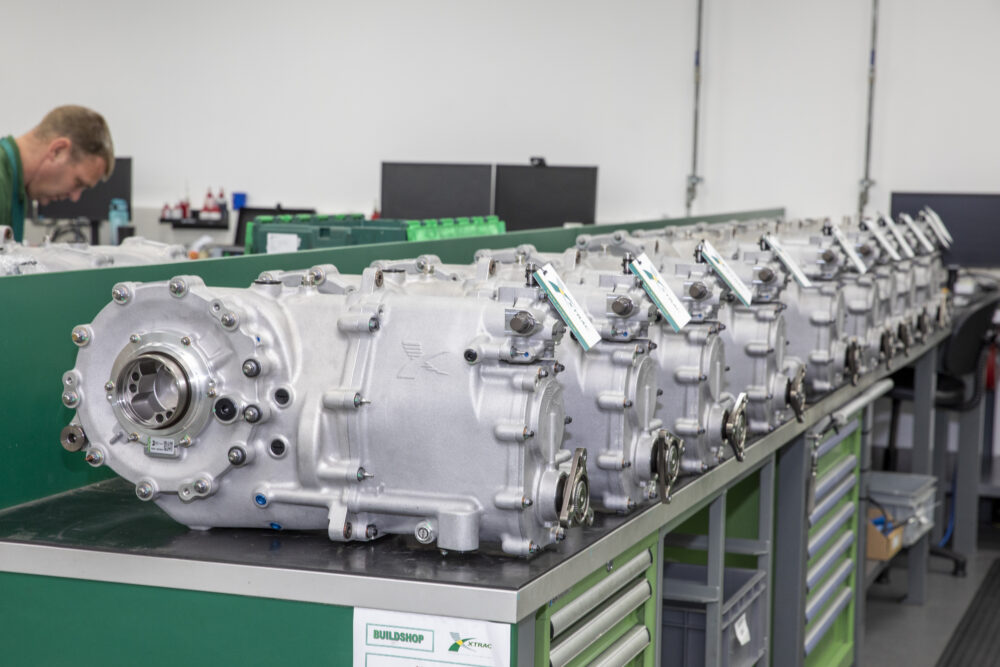

Following NASCAR’s announcement that Xtrac was selected to be the sole transmission and driveline supplier for the Next Gen Cup car, production has been progressing at full steam to ensure all teams will have sufficient stock for pre-season testing; by the Daytona 500 in February 2022, over 300 of Xtrac’s P1334 transmissions will have been supplied.

Prior to commencing the production phase, prototype transmissions completed an array of track testing ranging from short oval (1 mile), road course, intermediate oval (1.5 miles) and Super Speedway. In addition to Xtrac’s oil system gimbal testing, the P1334 drivetrain also completed extensive loaded dyno testing, simulating the most arduous duty cycle from Martinsville, wheel hop overloads, road course simulation and prolonged high-speed running to replicate Super Speedways.

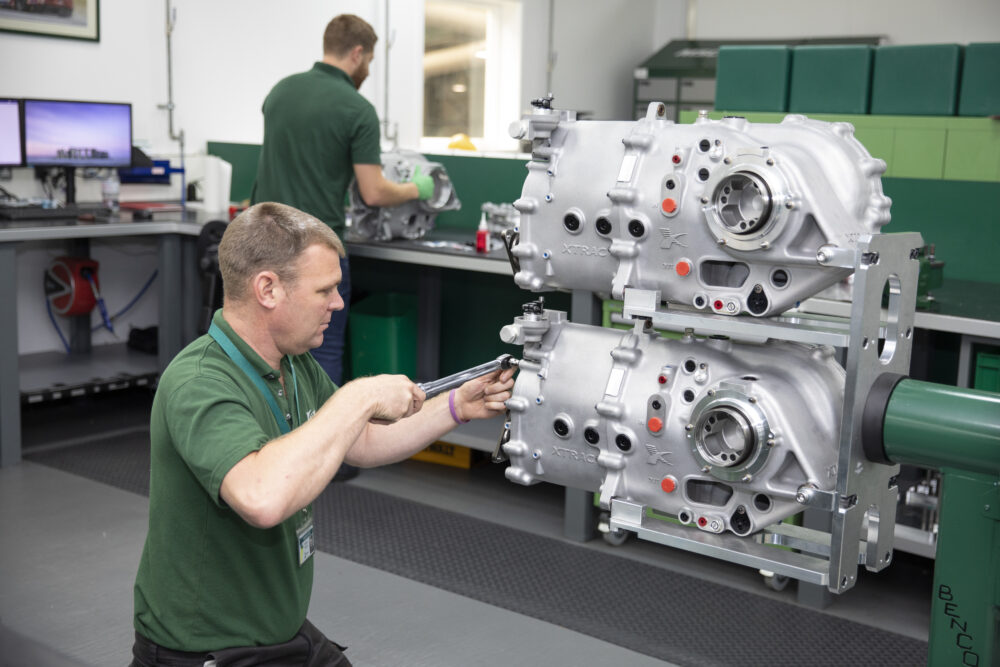

With validation testing complete, production started in earnest in spring 2021 and to date more than 200 off P1334 transmissions have been completed, with builds taking place both in the UK and at Xtrac’s expanded facility in Mooresville North Carolina.

The concept originally presented to NASCAR, was for three specifications of the P1334 transmission to suit low-speed, medium-speed and high-speed tracks. Each specification having fixed ratios and differential specifications to enable the team’s race and spare transmissions to be used at multiple tracks without servicing; the only exceptions being for the road courses where unique ratios have been selected to suit the tracks.

With the differential ramps and friction faces specified, teams can adjust the differential characteristics via an externally adjustable nitrogen-charged positive preload system, as has been used by Xtrac since 2012, when it was introduced for IndyCar and subsequently in a host of Prototype, GT, Rally and Formula cars.

Along with the P1334 transmission, Xtrac is supplying the Next Gen driveshafts including Xtrac high capacity tripode joints with 38mm rollers, as used in DPi and LMH / LMP1. The driveshaft assemblies feature a safety retention device, designed to keep the driveshaft shaft connected to the upright in the event of a crash.

The Next Gen transmission is located in the rear of the car to improve driver safety, allowing the driver’s seat to be mounted closer to the centreline of the chassis which could not be achieved with the traditional transmission and transmission tunnel; equally the new transmission location offers additional packaging benefits when considering electrification.

The P1334 transmission has been designed with an eye on the future and offers an easy transition to possible future hybrid drive installation in a similar fashion to Xtrac’s P1546 Hybrid Touring Car transmission, which was derived from the ultra-successful P1046 BTCC unit.

Supporting such a large number of teams and transmissions in the NASCAR series will be a huge task but one which Xtrac’s North American facility in Mooresville NC is ramping up towards, with an expansion of personnel in all areas of the business. If you would like to be part of this exciting programme, please visit our website’s careers section.